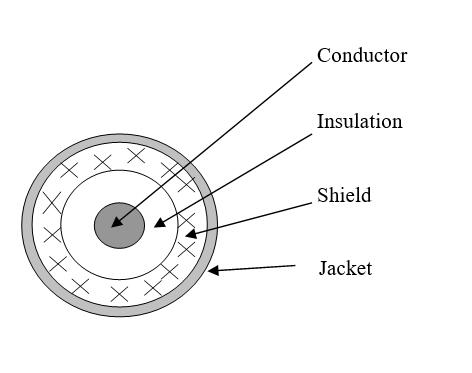

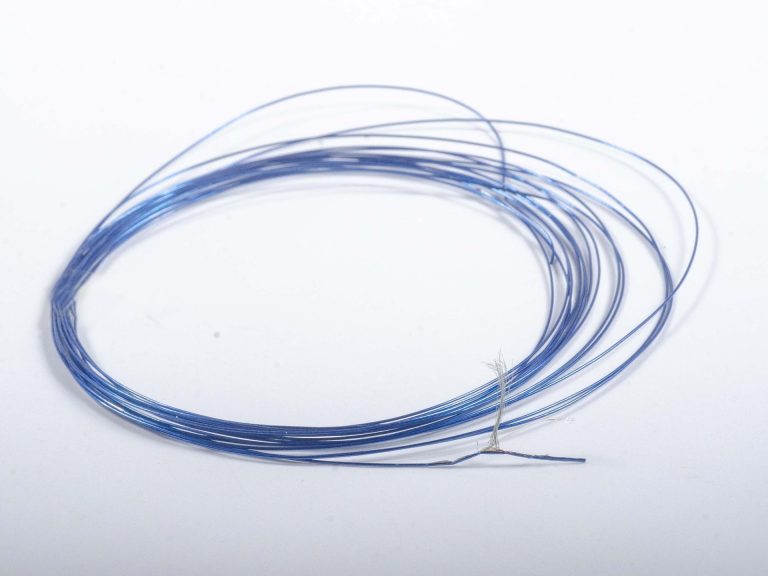

As one of the thinnest coaxial cables in the world, the 48AWG 50Ω coaxial wire represents a breakthrough in micro-coaxial technology. With an ultra-fine 0.17 ±0.002mm diameter, this cable pushes the boundaries of engineering, making it ideal for cutting-edge medical, aerospace, and high-frequency applications where extreme miniaturization is critical. Unlike most manufacturers who struggle to maintain electrical performance at this scale, our company stands as an industry leader, mastering the precision manufacturing of 48 AWG wire with exceptional signal integrity, low-loss transmission, and ultra-stable impedance. Engineered with silver-plated copper alloy wire for both conductor and shielding, and insulated with high-performance PFA, this cable ensures reliability in extreme environments, setting a new industry benchmark.

Feature

- World’s Thinnest Coaxial Cable: Ultra-fine 0.17 ±0.002mm diameter for extreme miniaturization.

- High-Purity Conductor & Shielding: Silver-plated copper alloy wire ensures excellent conductivity and EMI protection.

- Stable 50Ω Impedance: Optimized for high-frequency signal integrity with minimal loss.

- Advanced PFA Insulation & Outer Sheath: Provides superior thermal stability, chemical resistance, and mechanical durability.

- Low Insertion Loss & High Signal Fidelity: Designed for millimeter-wave communication, precision RF, and high-speed data transmission.

- Exceptional Flexibility & Durability: Withstands extreme bending and tight routing in compact devices.

- Industry-Leading Manufacturing Precision: One of the few global manufacturers capable of producing 48AWG wire with guaranteed electrical performance.

- Ideal for Cutting-Edge Applications: Used in minimally invasive medical devices, aerospace sensors, implantable electronics, and ultra-compact RF systems.

48AWG micro coaxial cable specifications

Breaking Barriers: The 48AWG Thinnest Coaxial Cable and Its Engineering Challenges

In the world of high-frequency, high-precision signal transmission, miniaturization is an ongoing challenge. As technology advances, industries such as medical imaging, endoscopic robotics, aerospace sensors, and compact RF communication systems demand ever-smaller interconnect solutions. Enter the 48AWG 50Ω thinnest coaxial cable, a revolutionary innovation that very few manufacturers can successfully produce while maintaining strict electrical performance standards.

The Technical Challenges of 48AWG Coaxial Wire

Producing a 48 AWG wire that remains truly coaxial—maintaining consistent impedance, shielding effectiveness, and signal integrity—is an engineering feat that only a handful of companies worldwide can achieve. Here’s why:

- Ultra-Fine Dimensional Control

- At 0.17 ±0.002mm, the cable’s conductor and shielding must be perfectly aligned to prevent signal inconsistencies.

- Even minor deviations in the dielectric layer can lead to impedance mismatches, causing signal degradation.

- Material Precision and Stability

- Traditional manufacturing techniques struggle to process silver-plated copper alloy wire at such a fine gauge without breakage or inconsistency.

- Ensuring uniform PFA insulation at this scale is a major challenge, requiring highly specialized extrusion processes.

- Shielding and EMI Protection

- Many ultra-thin cables suffer from inadequate shielding, leading to electromagnetic interference (EMI).

- Using silver-plated copper alloy as both the conductor and shield enhances conductivity while maintaining superior EMI protection.

- Manufacturing Yield and Consistency

- Most manufacturers experience low yield rates when attempting to produce 48AWG coaxial wire, leading to high costs and unreliable performance.

- Our advanced manufacturing process ensures a stable, repeatable production of the thinnest coaxial cable with guaranteed electrical performance.

Applications of 48AWG Thinnest Coaxial Cable

The demand for ultra-thin coaxial solutions is growing rapidly in industries where miniaturization is crucial. This 48 AWG wire is ideal for:

- Minimally Invasive Medical Devices – Used in next-generation endoscopes, catheters, and surgical robotics where ultra-fine cabling is essential.

- Aerospace & Defense – Essential for micro-sensors, satellite systems, and precision radar technologies.

- High-Frequency RF Systems – Supports millimeter-wave communications, 5G/6G antennas, and ultra-compact RF circuits.

- Wearable & Implantable Electronics – Perfect for biomedical monitoring systems, smart wearables, and neurostimulation devices.

Why We Lead the Industry in 48AWG Coaxial Wire Production

While many manufacturers can claim expertise in micro coax cables, only a few globally can consistently produce a 48AWG thinnest coaxial cable while ensuring:

✅ Stable 50Ω impedance for high-frequency applications.

✅ Low insertion loss and minimal signal attenuation.

✅ Superior shielding against EMI and crosstalk.

✅ Durability under extreme conditions (heat, chemicals, bending).