Precise, and Reliable x-ray tube high voltage cables — Designed for X-ray, DR, and CT Systems

Hiflexlink is a Medical X Ray High Voltage Cables manufacturer,mainly assembly X-ray high-voltage cables for 75kV and 90kV , which are designed for use with 125kV and 150kV X-ray tubes.

They are usually used in medical imaging equipment such as X-ray machines, DR systems, and CT scanners.

X ray cable(one end CA1 connector plug,the other end CA11 connector socket) is used to connect the X-ray tube to the high-voltage generator ,and compatible with brands like Siemens, GE, Philips, Shimadzu, Wandong, and Anjian.

As an Custom x ray cable manufacturer,we can only only custom the cables, length,both also the connector,s shape , including two connector types: straight and elbow.

Cable length is also customizable — standard lengths include 2meter, 4meter, 6meter, 8meter, 10meter, 12meter, 15meter, and 17meter.

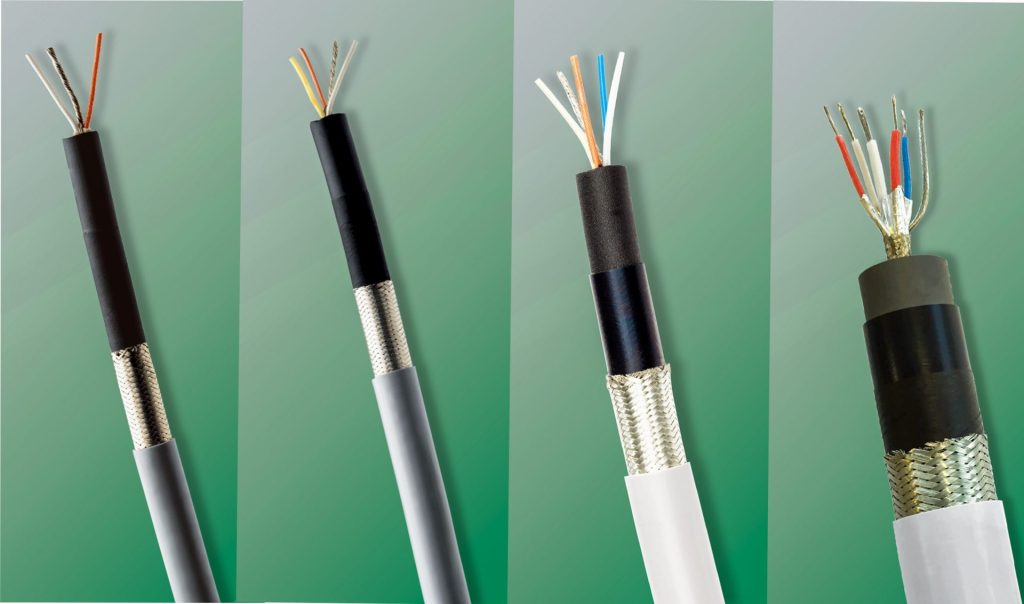

We also offer high-voltage cables without connectors, available in 3-core, 4-core, 5-core, and 6-core configurations to meet your specific requirements.

the x ray high voltage cable manufacturing and testing process

Be different from low voltage cable,many processing of x ray high voltage cable during the manufacturing and testing can not be done manually,it need to set up a special tools or testing conditions.in order to help you know th whole process and reduce your worry about the saftey issue

- Stripping: Automated rotary stripping for inner/middle layers & automatic core wire stripping

- Crimping: Auto crimping with dedicated dies for dimension consistency

- Welding: Precision welding with controlled parameters

- Dispensing: Latest automated dispensing machine ensures consistent adhesive ratio

- Potting & Curing: Enhanced oven curing for higher throughput

- Electrical Testing: Resistance testers & high voltage testers verify every unit

- Traceability: One QR code per cable for full tracking

- See the whole progress of “X-ray Cable assembly“

FAQ

Q: Can you provide X-ray cables without connectors?

A: Yes, we offer connector-less high-voltage wire options with customizable core counts (3–6 core).

Q: What lengths do you support?

A: Standard lengths range from 2 meters to 17 meters. Custom lengths are also available (please Consider the voltage drop with the length of the cable,conductor size may need to be increased)

Q: Are your products compatible with major brands?

A: Yes, our cables are compatible with Siemens, GE, Philips, Shimadzu, Wandong, Anjian, and others.

Q: Do you test every cable before shipment?

A: Absolutely. Each cable undergoes high-voltage and resistance testing to ensure performance and safety.