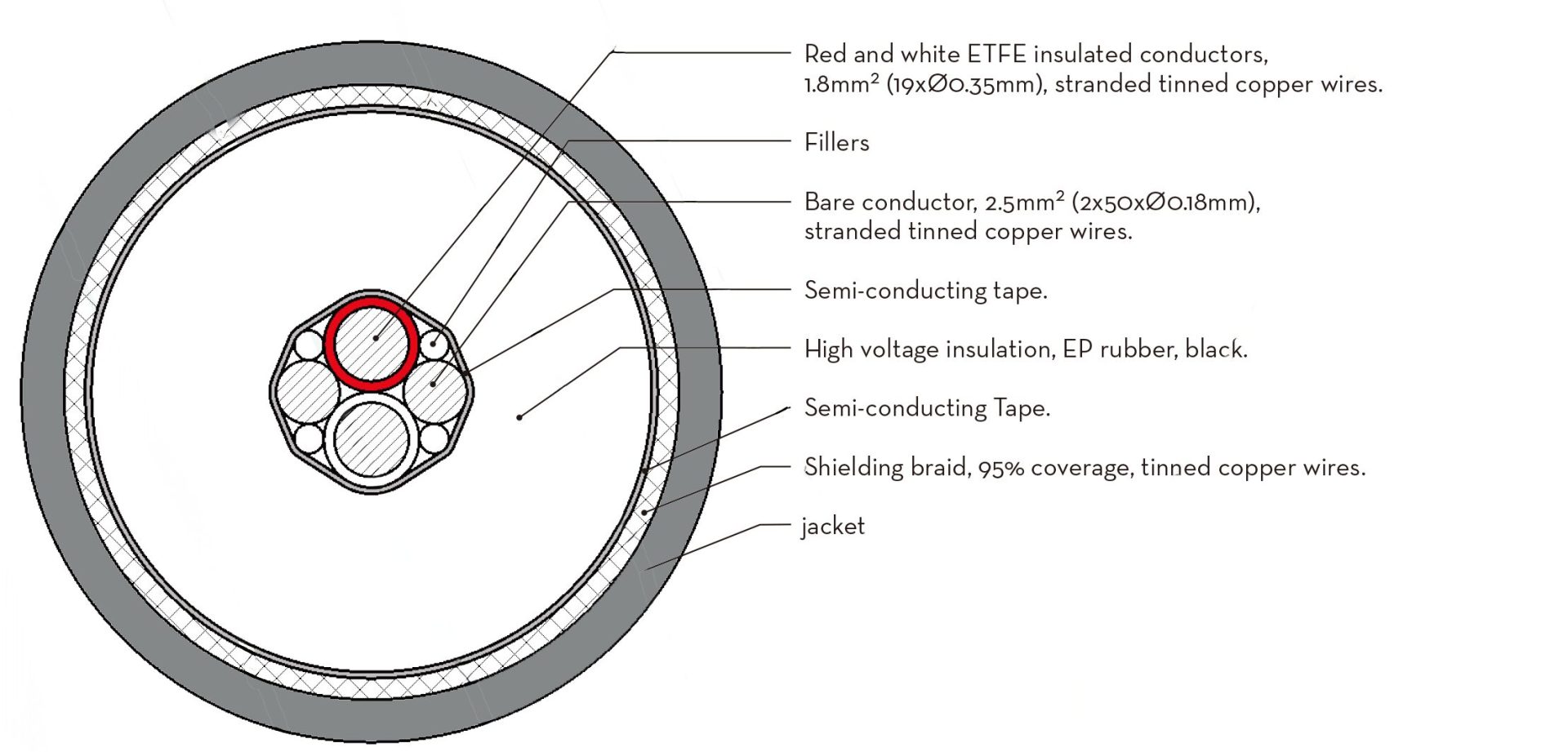

From the beginning-Cable design and extruding to a assembled X-ray cable with plug and socket.Our high-voltage cables are designed to support voltages from 75kV to 100kV and can operate continuously at temperatures up to 75°C.

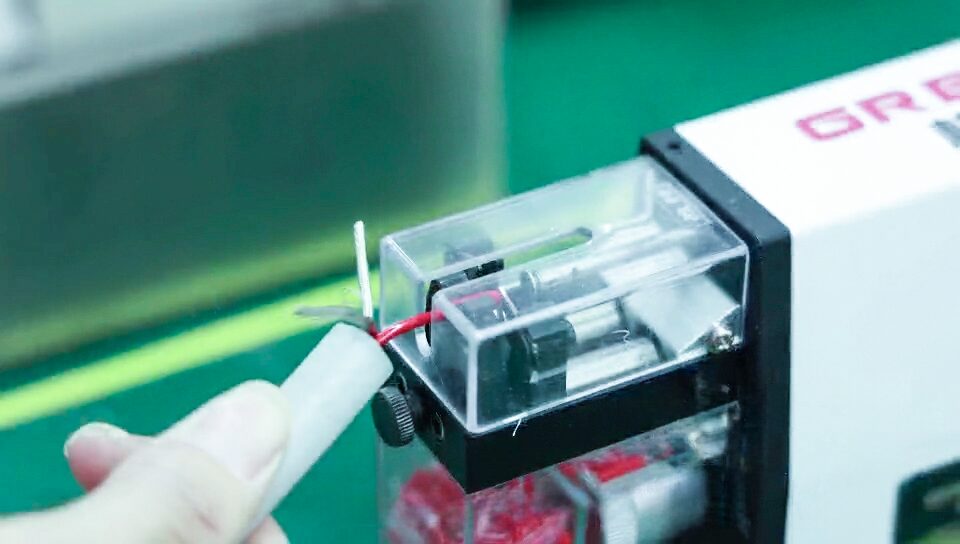

HiFlexlink has introduced advanced automation into its manufacturing process.

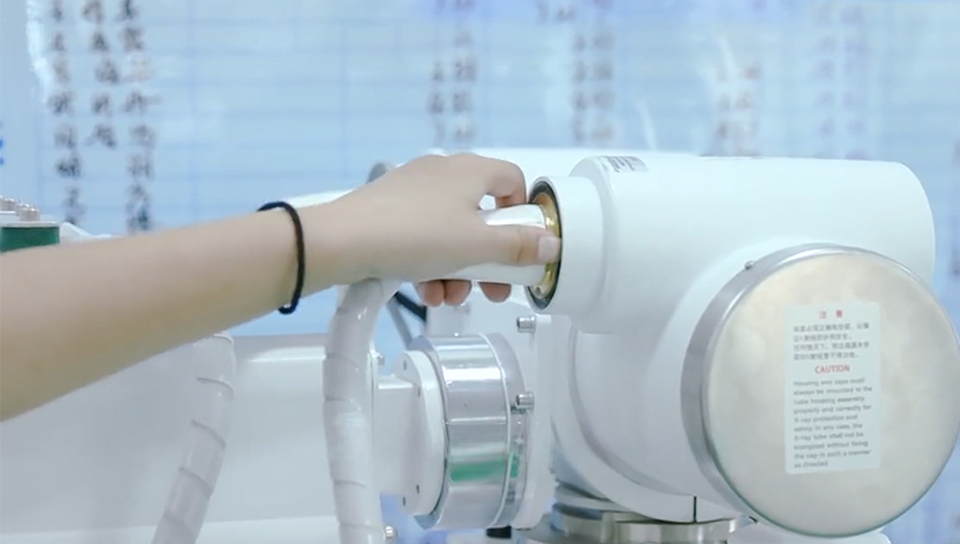

X-ray Cable assembly Steps

Once the program is entered, the machine applies adhesive with precision, ensuring consistent volume and ratios across every product.

Testing

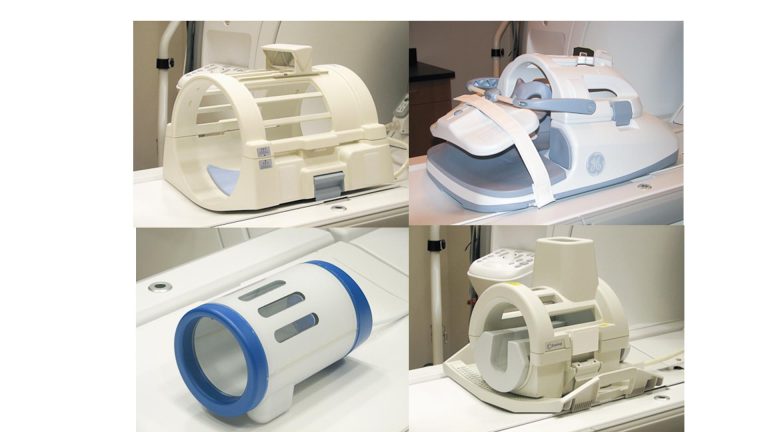

Installation