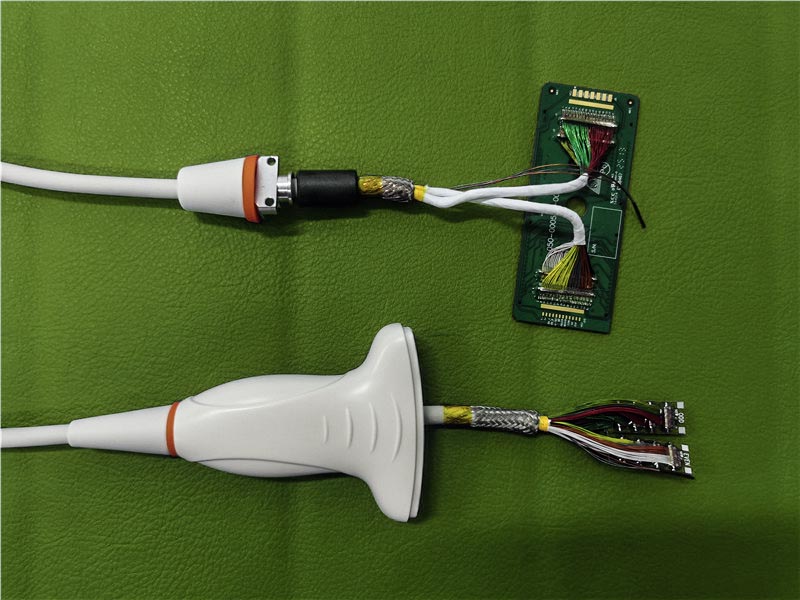

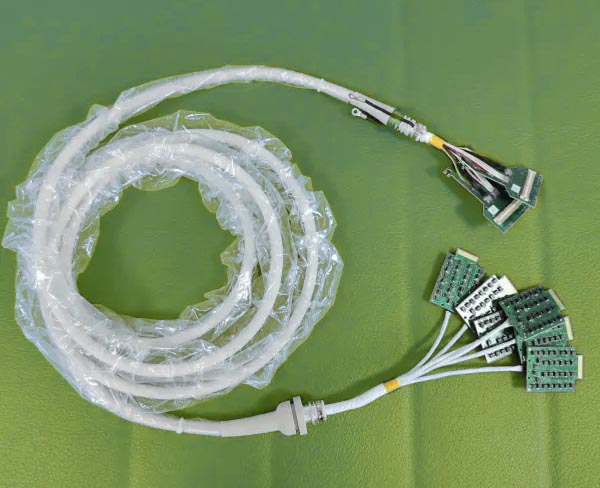

Semi-finished ultrasound cable solutions for probe manufacturers and repair service providers

Our PCB pre-soldered ultrasound probe cable assemblies conbines our advantage of raw cable production and full transducer integration. By pre-soldering PCBs on both ends and ensuring precise cable routing and shielding.We eliminate the most complex steps in the assembly process while leaving flexibility for clients to finalize the probe structure with their own matrix or crystal components. This approach is especially valuable for overseas probe manufacturers who has no facility and technology,and seek to reduce production time and error rates, as well as repair service providers who need reliable, ready-to-integrate cable solutions for fast turnaround. With consistent electrical performance, bio-compatible materials, and customizable lengths and connectors, our assemblies empower OEMs and repair specialists to focus on what they do best — building and restoring high-performance ultrasound probes. Start your visit to our ultrasound cable assembly workshop video on youtube now !!!

Introduction to Ultrasound Technology

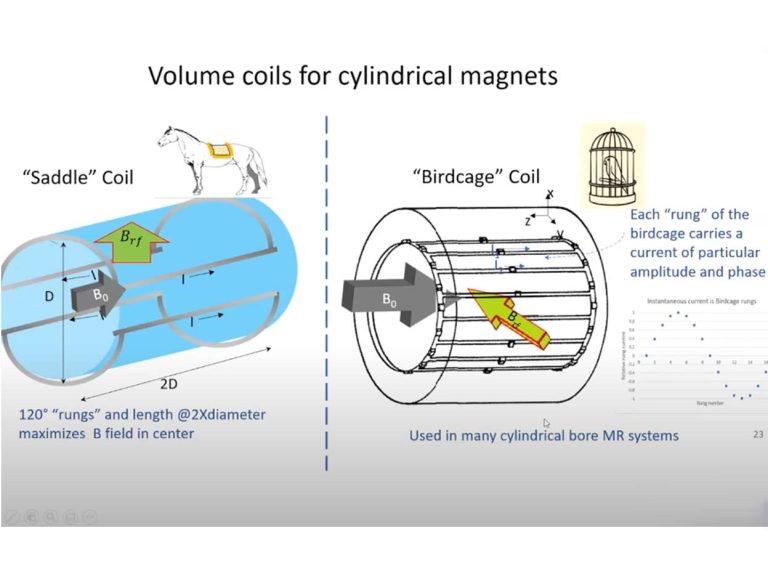

Ultrasonic sensing technology is used in many industrial applications, with medical imaging being one of the most important. In clinical diagnostics or Ultrasound-based Disease Screening and Preventive Care, ultrasound is a safe, non-invasive, and highly accurate way to detect internal conditions by providing real-time imaging, without radiation exposure and harm to patient,so it becomes a preferred and affordable tool for doctors and patients.

Type A ultrasonography diagnostics use sound wave reflections from varying tissue acoustic impedance. Displaying these echoes on a monitor reveals interior architecture.

Type B ultrasonic diagnostics (brightness mode) render echo amplitudes as two-dimensional brightness levels. Type B displays real-time tissue cross-sectional images instead of signal spikes. It is the most extensively used clinical ultrasound mode because each echo point is shown as a pixel whose brightness matches the returned signal, making organ architecture, lesions, and movement easier to visualize.

Importance of Cable Quality in Ultrasound Imaging

Key Components of a Piezoelectric Ultrasound Probe

Each probe contains elements like:

• Piezoelectric wafers (usually quartz or ceramic)

• Damping blocks

• EMI shielding and protective housing

• Signal cable and connector interfaces

The piezoelectric wafer plays a core role in converting electrical signals into ultrasound and vice versa, enabling both transmission and reception. Damping materials help reduce noise and echo artifacts, improving image resolution.

what we offer

We manufacture custom ultrasound probe cable assemblies — the critical cable portion connecting the probe head to the system. Our assemblies are equipped with pre-soldered PCBs at both ends, excluding the matrix and piezo crystal, which allows flexible final assembly at the customer’s side.

Who Needs This Product

• Ultrasound probe manufacturers

• Medical device /Ultrasond probe/Transducer repair companies

• OEMs and R&D labs developing new probes

• Distributors of semi-finished medical components

Key Features of our Ultrasound probe assembly service

• Supports micro coax or differential signal wires (36–44 AWG coaxial,Low capacitance and high capacitance version available)

• Pre-soldered PCBs at both ends

• High-flex, medical-grade shielding

• Compatible with GE, Philips, Siemens, Mindray, and more

Applications

• New probe production lines

• Refurbishment of used probes

• Prototype or clinical R&D projects

Brands Ultrasound probe Compatible Cable Assemblies

Our Service include following brands compatible probe cable assembly ,not only limit to .We support repair and manufacturing for most major brands, including: GE, PHILIPS, SIEMENS, ESAOTE, SAMSUNG, MEDISON, MINDRAY, ALOKA, HITACHI, TOSHIBA, SONOSITE, FUKUDA, CHISON, SIUI, EDAN, EMPROR, SONOSCAPE, Landwind, and more.

• Philips L12‑5 Linear Array Cable Assembly

• GE C1‑6‑D Convex Cable Assembly

• Philips C5‑1 Cable Assembly for IE33/IU22

• Philips C5‑1 Cable Assembly for CX50

• Mindray C5-2e New Convex Array

• Toshiba PLT-805AT Transducer

Useful tips

Evaluate Manufacturing Capabilities of an Ultrasound Probe Cable Assembly Provider

- CCD-guided micro-soldering

- Clean and reliable cable routing

- OEM/ODM friendly

- Global shipping and responsive service

Best Practices & Maintenance

- Ensure compatibility with probe system

- Avoid excessive bending or twisting

- Clean only with non-corrosive solutions

- Replace if signal transmission degrades